ideas take shape

We deliver services for

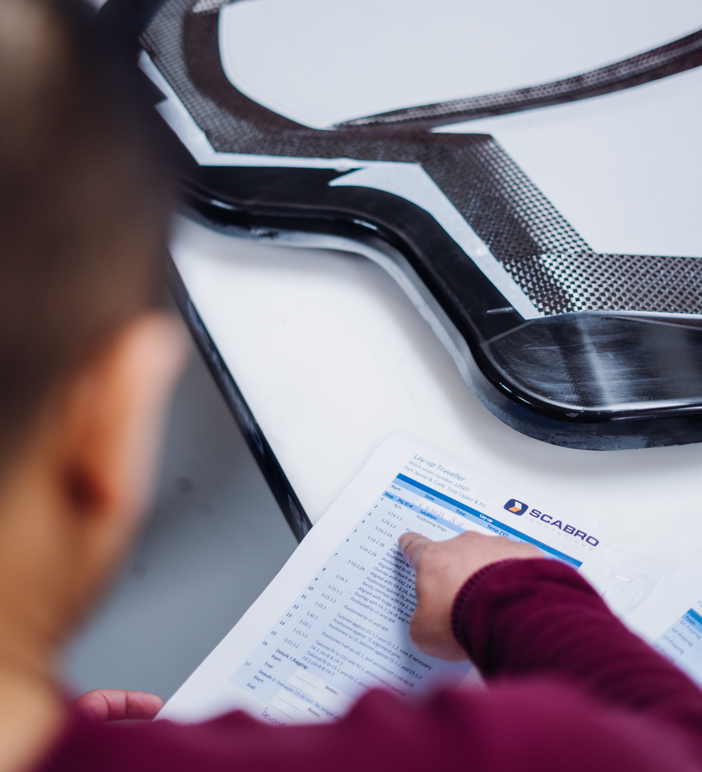

Prototyping

We offer exceptional prototyping services with an emphasis on quality, speed and cost-effectiveness. Together we co-design, meeting our customers specifications, integrating low-weight and complex geometries while anticipating the future manufacturing process.

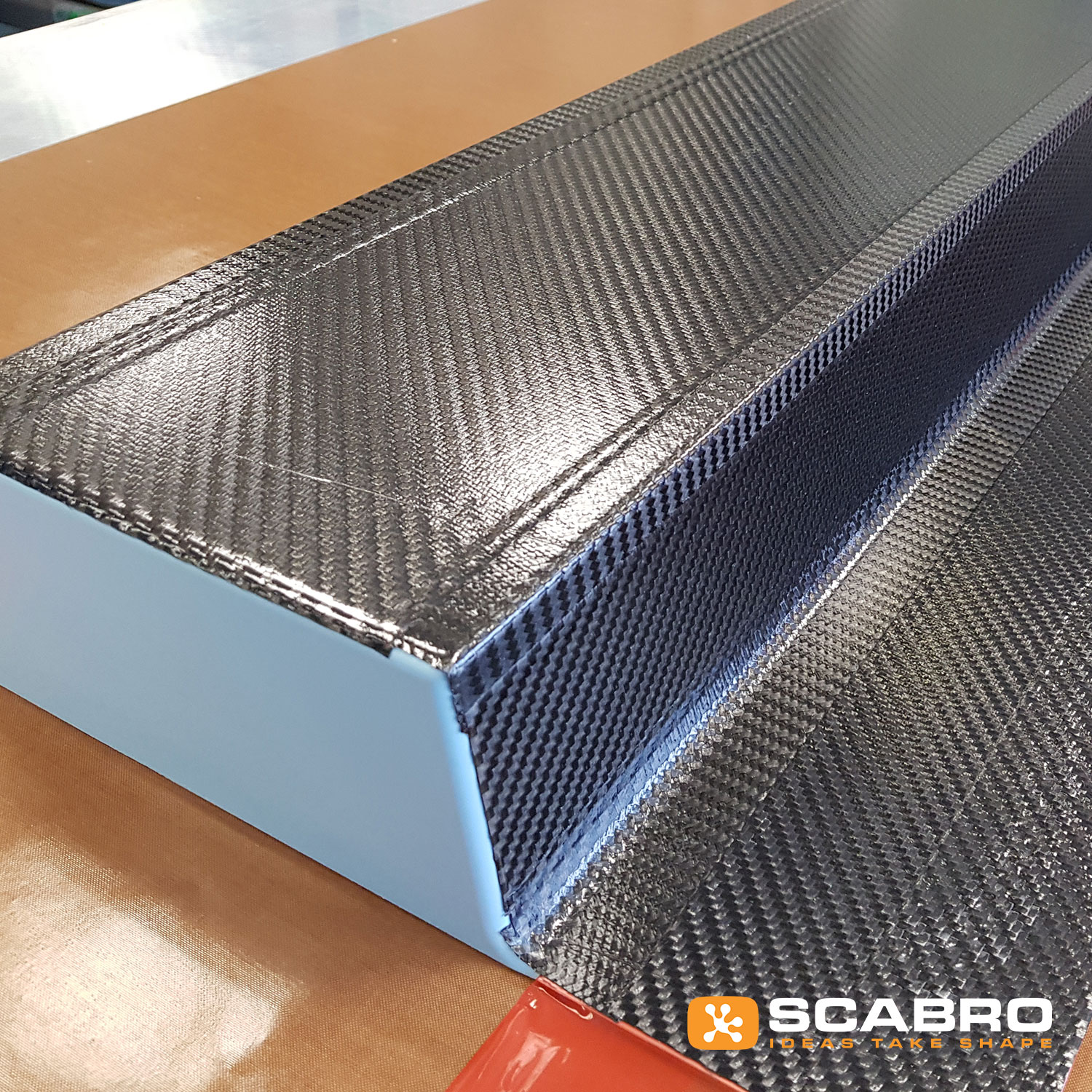

UAS Prototypes

Our clients value our the high-quality prototypes that closely match their design specifications. For Scabro this automatically includes attention to detail, accuracy, and the ability to integrate complex geometries while considering the future production process

Speed and Efficiency

Time-to-market is critical for many businesses. Scabro offers rapid prototyping and quick turnaround times, allowing our customers to iterate and refine their designs promptly.

Technical Expertise

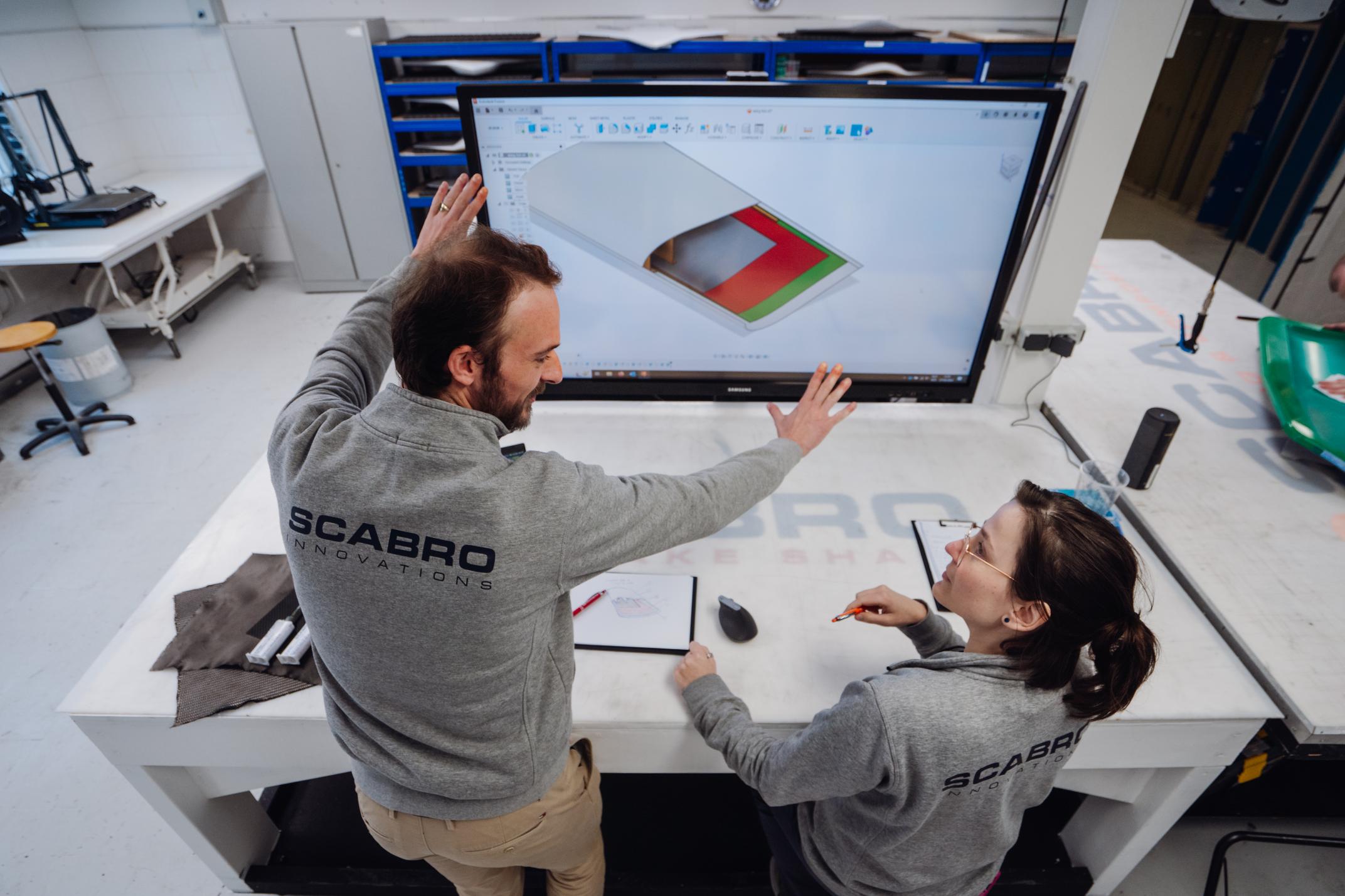

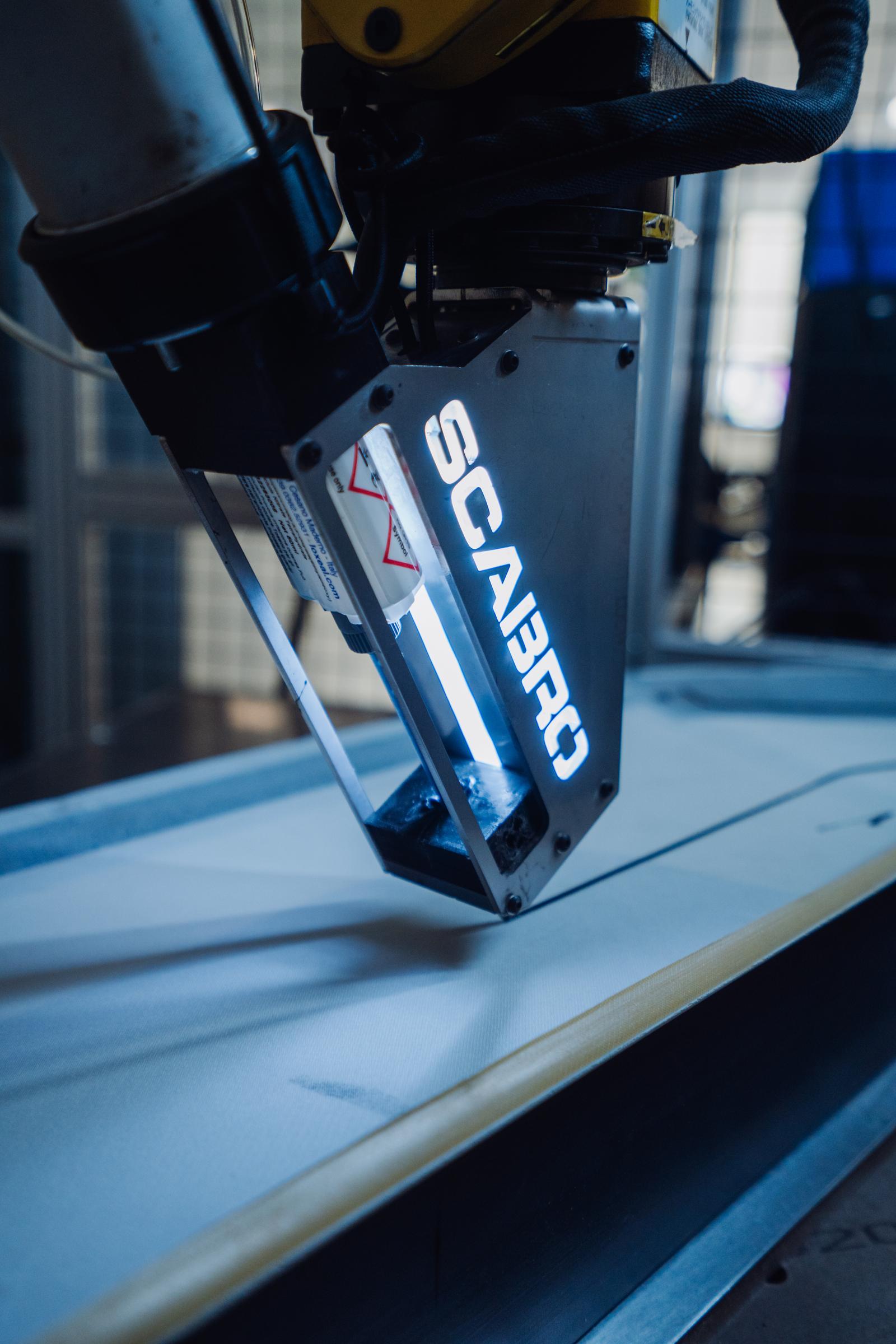

Our team of composite technicians and skilled aeronautical engineers, specialized in materials and automation are highly valued by our clients. All have a university of applied science composites background and hands on experience, which often result in great practical solutions!

Range of Services

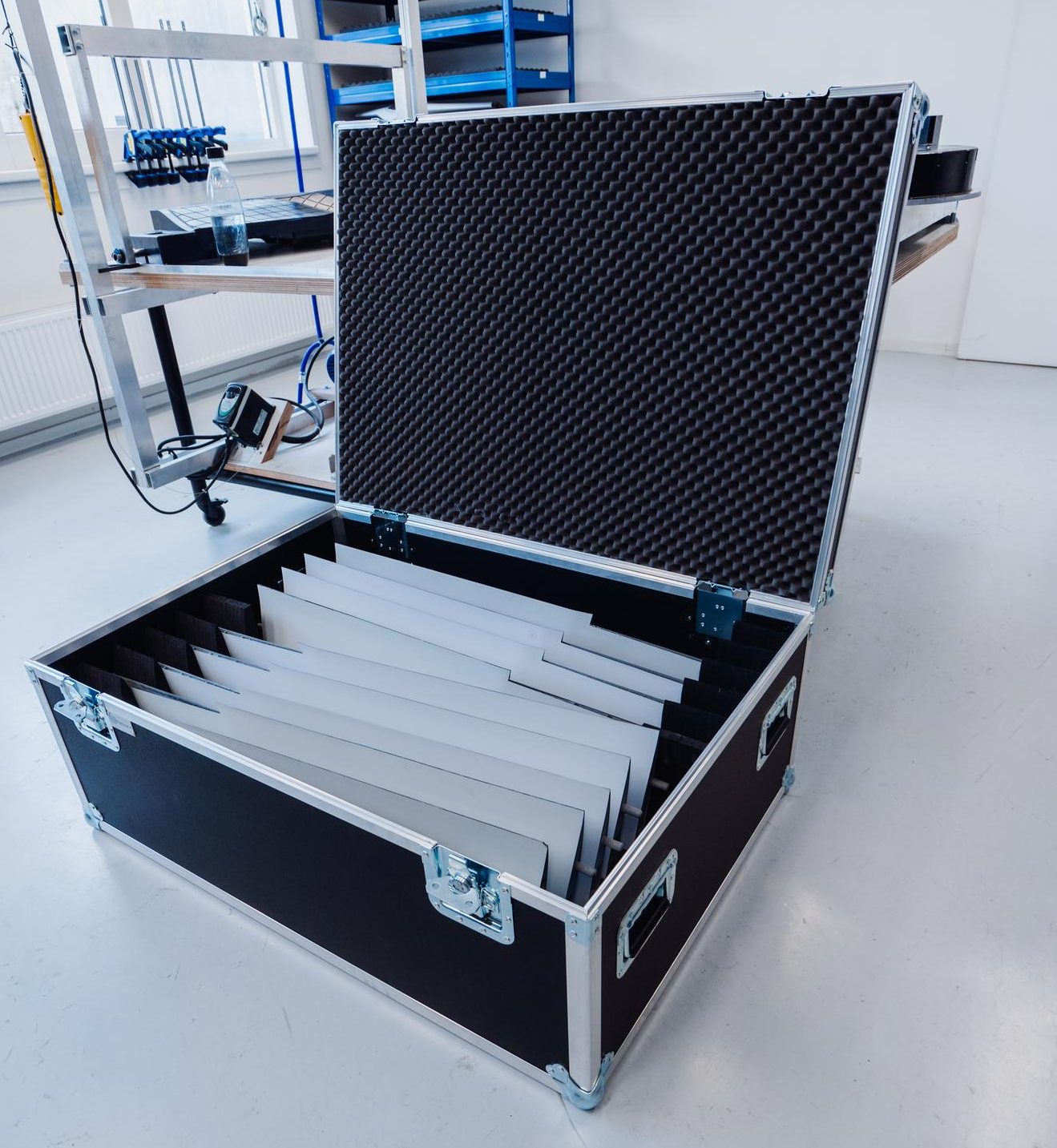

We offer a wide range of prototyping services, including in-house additive manufacturing (3D printing), CNC machining, infusion, and many more techniques that we can offer through partners in our worldwide “plastics” network that we started building in 2007. This versatility allows us to choose the most suitable prototyping method for any specific project needs.

Scabro has extensive, decades long, experience and expertise in the supply, design and manufacturing of composite tooling for fiber reinforced plastic (FRP) components.

Tooling

An efficient composite production line can not excist without quality tooling. Having the knowledge and capability to produce our own masters, mould, jigs and fixtures gives many advantages such as controlling the quality, speed, flexibility and costs. Only high quality and effective tools allow for the production of high-quality and effective composite parts.

Expertise in Composite Tooling

Decades of developping and serving the tooling & composite market in North-West Europe made us a specialist in a vast network of experienced modelmakers. This results in creative, sustainable, precise, and reliable molds and tools.

Design and Engineering

Our tooling designs are always cutting-edge, cost-effective and have high manufacturability and performance. We use all major available CAD/CAM software throughout the whole design and manufacturing process.

Cost-Effectiveness

While quality is paramount, we guarantee tooling solutions that offer good value for money on the long run while always ensuring dimensional accuracy and surface finish requirements.

Quality Materials

High-quality tooling is essential when producing composite components with consistent quality and performance. We work with the world's largest producer of high-performance styling, modeling, and working boards. These stand for high quality "made in Germany“ and excellent mechanical properties.

Collaboration and flexibility

We like to collaborate. This could result in us assisting in the production of high-end prepreg tooling in your facility, or we train your team in our workshop or at one of our global partners.

Small series production

It begins with an ideaBut designers often have a long way to go before a perfect composite part is made in a cost-efficient productionline. Here at Scabro we aim to produce aerospace quality at automotive pricing. Want to to know how we succeeded in disrupting the conservative aerospace, automotive and superyacht industry? Get us in as soon as you have an idea, or even as late when having sold your prototype and you need to scale up fast!

High volume production

We produce aerospace quality at automotive pricing. At Scabro we know that designers have a long way to go before a perfect composite part is made in a cost-efficient manufactoringline. Are you interested in learning how we succeeded in disrupting the conservative aviation and superyacht industry? Get it touch whenever your succesfull prototypeneeds to be scaled up fast and see your ideas take shape!

Production process

By establishing a large-scale board production facility. Scabro standardized manufacturing processes, implemented quality controls, and began developing new and innovative surfboard building techniques. Scabro’s ability to mass product and export into the world market has allowed for a rapid growth for its OEM customers as well as through its own brand.

Unmanned valley, TU Delft

Unmanned Valley is convinced that unmanned and autonomous technology offers solutions for issues related to the energy transition, personnel shortages, logistics, defense, agriculture and much more. We bring together knowledge, supply and demand from the entire chain. The former Naval Air Station has been converted in recent years into the Dutch center for unmanned technology.

Visit their website

About Scabro

Our mission

Our mission is to make the advantages of mass manufactured composite platforms accessible for innovative minds. With our extensive expertise, resources and network, we enable customers to realize their visions with aerospace-grade quality at compelling pricing, revolutionizing the industry and uav landscape.

Our values

Our values reflect our commitment to innovation, excellence, transparency and customer centricity, while providing aerospace quality at automotive pricing. These 6 values underwrite that which is in our DNA.

1

Innovation: We embrace creativity and ingenuity to continually push the boundaries of composite manufacturing, seeking practical, no-nonsense, low-cost and novel solutions to meet customer needs.

2

Quality Excellence: At Scabro we maintain unwavering commitment to delivering repeatable aerospace-grade quality in every aspect of our products, ensuring customer satisfaction and trust.

3

Collaboration: We foster collaborative partnerships with our customers, suppliers, and stakeholders to co-create new solutions and drive mutual success.

4

Integrity: Our policy demands us to operate with honesty, transparency, and ethical conduct in all interactions, upholding the highest standards of integrity and accountability.

5

Customer-Centricity: Our customers' needs and aspirations are our top priority. We go above and beyond to surpass their expectations, offering personalized solutions and delivering exceptional service with a touch of timeless hospitality.

6

Sustainability: Since the start of Scabro we have embraced environmental responsibility by promoting sustainable bio-resins and natural fibers throughout our operations, the best example being the worlds biggest bio-bridge at 67m long, based in Friesland, The Netherlands.

2008

Scabro is born

Founder Jaap Ruwaard starts serving the Benelux area by distributing epoxy resins and toolingboartds for a German / Swiss manufacturer. The following years the portfolio quickly grew serving both the Tooling & Composite markets.

2013

Composites Innovation Event

Simultaneously with the 5-year anniversary, Scabro organized the “Composites Innovation Event”: Together with 40 international industry leaders we welcomed more than 300 composite enthousiast, getting them up to date on the latest innovations in composites.

2019

Start of production

After moving to its current facility, Scabro started to experiment with innovative materials, intensifying the relationships with many R&D departments of international suppliers. Our lab turned out to be a perfect incubator for small series production such as the world first “Recycled Carbon Chair” on display in several musea worldwide.

2023

Worldwide network

With a Holland-based team of 25 people, a fully fitted aviation grade composite workshop, a gigantic international network consisting of raw material manufacturers, engineering companies, tooling specialist, composite innovators and visionairs, Scabro has its spotlight on providing cutting edge, turn-key solutions for massproducing composite airframes for Unmanned Aerial Systems (UAS). Now, let's get your ideas to take shape!